SENSOR TYPES AND APPLICATION - WIRELESS

Our wireless enabled sensors provide real-time monitoring of critical manufacturing and industrial equipment. By capturing precise data on machine performance, environment, and energy usage, we help you reduce downtime, optimize operations, and prevent costly downtimes.

Temperature Sensor

Used to monitor heat levels in machines, processes, or environments.

Monitor motor, bearing, and gearbox temperatures to prevent overheating.

Control temperature in industrial ovens, furnaces, and kilns.

Track cooling system performance in chillers and HVAC systems.

Ensure proper temperature in food, pharmaceutical, and chemical production.

Detect abnormal heat rise in electrical panels or transformers.

Pressure Sensor

Measures pressure in gases or liquids for system performance and safety.

Monitor hydraulic and pneumatic system pressure.

Detect pump or compressor efficiency and performance issues.

Control steam pressure in boilers and process lines.

Measure air pressure in HVAC ducts and cleanroom systems.

Monitor pipeline or vessel pressure for leak detection.

Flow Sensor (Clamp-On)

Monitors the rate of liquid or gas movement through pipes.

Measure water, coolant, or oil flow in industrial equipment.

Monitor air flow in ventilation and pneumatic systems.

Verify proper lubricant circulation in bearings and gearboxes.

Track chemical or fuel flow in process lines.

Detect flow blockages or pump performance changes.

Level Sensor

Detects and measures the level of liquids, powders, or solids in tanks and containers.

Monitor tank levels for water, oil, or chemical storage.

Control automatic refilling or emptying systems.

Detect leaks or overflow conditions.

Manage fuel levels in industrial generators or engines.

Measure material levels in silos and hoppers.

Vibration Sensor

Measures vibration to detect mechanical imbalance or wear.

Monitor motor and pump vibration for early fault detection.

Detect bearing wear or looseness in rotating machinery.

Track fan, blower, and compressor performance.

Monitor vibration in conveyors, mixers, and gearboxes.

Identify excessive vibration that may affect precision equipment.

Humidity/Temperature Sensor

Measures the amount of moisture in the air or environment.

Control humidity in production rooms, warehouses, or cleanrooms.

Monitor moisture-sensitive manufacturing processes.

Prevent corrosion or condensation inside electrical cabinets.

Track environmental conditions for food or pharmaceutical storage.

Optimize HVAC system performance and air comfort.

Current / Power Sensor

Measures current draw and power usage in electrical systems.

Monitor energy consumption of motors and machines.

Detect overloads or phase imbalance in electrical circuits.

Identify idle or underperforming equipment.

Prevent overheating or damage caused by excessive current.

Support energy optimization and predictive maintenance.

Voltage Sensor

Measures electrical potential and system health.

Monitor voltage stability and supply quality.

Detect drops or spikes in power delivery to machines.

Ensure stable power to PLCs, control panels, or sensors.

Identify electrical faults in panels or distribution systems.

Support power quality analysis and load balancing.

RPM / Speed Sensor (Tachometer)

Measures rotational speed of shafts, motors, and rotating parts.

Track motor or turbine speed to detect performance changes.

Verify proper operation of fans, conveyors, and mixers.

Detect mechanical slip or belt wear.

Correlate speed data with vibration or temperature trends.

Support process control in manufacturing systems.

Proximity Sensor

Detects the presence or position of an object without physical contact.

Confirm part or product position on conveyors.

Detect object presence in assembly automation systems.

Monitor machine door or safety guard position.

Control robotic or pick-and-place positioning.

Count parts or detect motion for machine control.

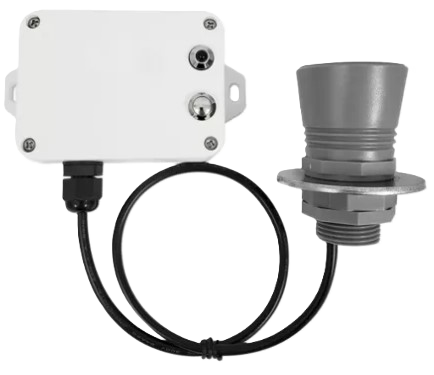

Ultrasonic / Acoustic Sensor

Uses sound waves to measure distance, flow, or detect abnormal sounds.

Non-contact level measurement in tanks.

Leak detection in compressed air or gas systems.

Flow measurement in pipes (ultrasonic clamp-on).

Detect cavitation or abnormal sound in pumps and valves.

Monitor acoustic emissions for predictive maintenance.

Gas Sensor

Detects concentration of gases or vapors in the air.

Monitor CO₂ or O₂ levels in confined industrial areas.

Detect flammable or toxic gases (CH₄, H₂S, CO, etc.).

Control ventilation in paint, chemical, or fuel storage areas.

Ensure worker safety in confined or hazardous environments.

Support environmental compliance and air quality control.

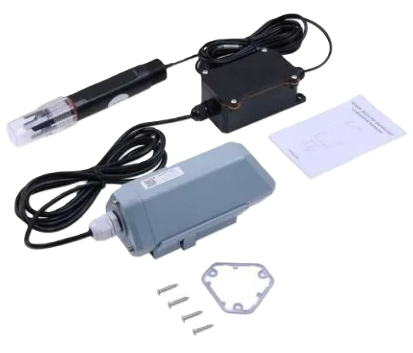

pH Sensor

Measures acidity or alkalinity in liquids.

Monitor chemical balance in water treatment systems.

Control process pH in food and beverage production.

Ensure proper neutralization in wastewater systems.

Maintain correct pH in cooling or boiler water.

Support chemical dosing and quality control.

Conductivity Sensor

Measures a liquid’s ability to conduct electricity, indicating purity or concentration.

Monitor water quality in treatment plants or chillers.

Detect contamination in industrial process water.

Verify chemical mixture concentration.

Control cleaning (CIP) systems in food and pharma processes.

Support process optimization and compliance.

Strain / Load Sensor

Measures force, tension, or weight applied to a structure or component.

Monitor structural load in cranes, lifts, or supports.

Measure press or clamping forces in manufacturing machines.

Detect overloading in conveyors or weigh systems.

Track mechanical stress in bridges or heavy equipment.

Support predictive maintenance in high-stress machinery.

Vibration + Temperature Combo Sensor

Monitors both vibration and surface temperature simultaneously.

Provides dual insight into motor or pump health.

Detects overheating and vibration imbalance together.

Ideal for compact IoT predictive maintenance setups.

Reduces need for multiple sensor installations.

Integrates easily with cloud dashboards for early fault detection.

Sound / Noise Sensor

Monitors sound levels or frequency changes.

Detect unusual noise from bearings, fans, or motors.

Monitor acoustic comfort in work environments.

Identify air leaks in pneumatic systems.

Support NVH-like monitoring for noise compliance.

Track factory noise exposure for safety compliance.

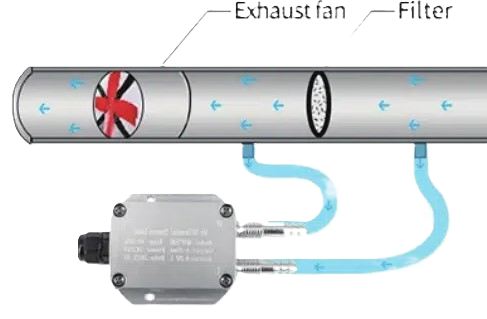

Differential Pressure Sensor

Measures pressure difference between two points.

Monitor filter health in HVAC or air handling units.

Track flow restriction in process lines.

Measure pressure drop across pumps or valves.

Detect clogged filters or pipes.

Control cleanroom air balance.